SHARE WITH FRIENDS:

Standardization methods

Plan:

-

Standardization methods.

-

Parametric standardization o 'specific characteristics.

-

Mahsoot haqin'data standardization and coding;

Basic phrases: homogenization, sorting method, aggregation, bar code, parametric standardization.

9.1. Standardization methods

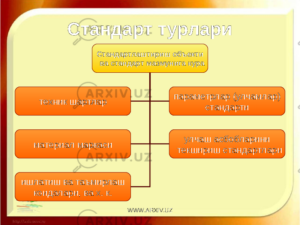

We can take homogenization, aggregation and classification as widespread methods of standardization (Figure 9.1). It is with the help of these methods that mutual interchangeability can be ensured.

9.1 - picture. Standardization methods.

Method of homogenization. In UzDST 1.0 – 92, the term integration is explained as follows:

Homogenization – choosing the optimal number of sizes or types of products, processes and services necessary to satisfy a particular need. This is also called unification. This word is Latin uni – one, unio – unity (unity) means.

Unification can be done at the expense of new creations or at the expense of simple reduction (simplification) in order to achieve the greatest technical and economic efficiency.

Homogenization is mainly carried out at 3 levels:

- enterprise level;

– at the network level;

- at the intersectoral level.

Recently, international integration is also developing widely.

Homogenization is carried out in a certain sequence. First of all, its direction, type and level are determined. Then, the drawings of the items to be consolidated and their analytical data are collected, and these drawings are classified according to the purpose set before them. After that, either a new design is developed, or one that can replace the existing ones is selected.

The degree of homogenization can be determined on the basis of the coefficient of application on the scale of four dimensions:

Kt=100(n – n0)/not

Here: n is the total number of four-dimensional items; n0 – the number of four dimensions selected.

Sorting method. The type method of standardization is a method aimed at determining object types for a complex that is considered as the main (base) in creating different objects that are close to each other in terms of functional tasks.

Sorting is sometimes called "base construction". Because in the process of sorting, an object is selected that is typical of the obtained set according to its optimal properties, and when a specific object - a product or a technological process is accepted, the selected object can be changed only partially. Thus, sorting is the application of a large number of functions to a small number of objects, thereby ensuring the preservation of objects of a particular type in a given set.

The efficiency of the type is based on the use of previously checked and tested solutions during the production of a new item, speeding up production preparation and reducing the cost of production, easing the conditions of use of individual type objects and their modification.

Sorting develops in three main directions among effective methods of standardization.

- standardization of certain types of technological processes;

- standardization of items of general importance;

- creation of regulatory documents defining the procedure for performing certain tasks, actions, tests or calculations.

In many production systems, in cases where it is necessary to quickly change the constructions of the product, it is important to create technological processes that allow to use them in the preparation of particular types of details and parts.

Aggregation method. Aggregation is a method of creating and using machines, tools and equipment consisting of separate, standardized, unified parts that are reusable for the creation of various items based on geometric and functional interchangeability.

Aggregation expands the fields of operation of machines and equipment, extends their service life, and facilitates their use.

Another important feature of aggregation is the increase in the nomenclature of machines and equipment due to modification of the main types. In addition, aggregated equipment will have constructive reversibility. This makes it possible to re-use standard aggregates and parts in reconfiguration of production facilities and adaptations when transitioning to new types of products.

The principle of aggregation is widely used in the creation of test-measuring devices consisting of unified electronic blocks, measuring transducers and elements.

9.2. Peculiarities of parametric standardization

The variety of items, parameters and dimensions is regulated (limited) by parametric standards.

As a result of the application of parametric standardization, the irregular and numerous nomenclature of items is avoided. In addition, an opportunity is created for mutual adaptation and unification of products, problems in the supply of spare parts are eliminated.

The essence of parametric standardization is that the parameters and dimensions of grossly produced items are determined not freely and independently, but according to a series of specially selected (communicated) numbers, that is, to a series of numbers that are more divisible by communication compared to other numbers. .

Parametric standardization is widely used. We can see this in the sizes of the legs, head and other clothes, the sizes of bolts, nuts and so on.

Selected numbers are characterized by certain mathematical laws. For example, the simplest dialogue is selected based on an arithmetic progression of a series of numbers. In this case, the difference between one number in the series and the previous and next numbers is always constant. For example:

-

a) increasing with a difference of 1; 1 – 2 – 3 – 4 – 5 – ….;

-

b) increasing with a difference of 2; 1 – 3 – 5 – 6 – 7 – …;

-

c) decreasing with a difference of 0,1: 1 – 0,9 – 0,8 – 0,7 – …

We can find the arbitrary term of the arithmetic progression from the following expression:

an=ai+d(n – 1),

in this, ai - the first term of the progression, d - the difference of the progressive, n - the order of the selected number (term).

Number series based on arithmetic progressions are less commonly used in parametric standards, but such standards do exist. For example, the dimensions of the diameters of some types of bearings, the dimensions of the shoes, and so on.

The main advantage of parametric standards based on arithmetic progression is its simplicity. The disadvantage is that it is relatively uneven. That is, in an increasing arithmetic progression with a difference of 1, the number 2 is more than 1 by 100%, the number 10 is more than 9% by 11, and the number 100 is more than 99 by 1%. As a result, large numbers are more common than small numbers and do not fully satisfy the requirements.

To overcome this drawback, cross sections based on arithmetic progression are often used. For example, the series of coins is based on this:

1 - 2 - 3 - 5 - 10 - 15 - 20

Geometric progression has been used since ancient times to create a series of selected numbers. In a geometric progression, if you remember, the ratio of the next number to the previous number remains constant. For example:

-

a) an increasing number with a divisor of 1,1: 1 – 1,1 – 1,21 – 1,33…;

-

b) a decreasing number with a divisor of 0,1: 1 – 0,1 – 0,01 – 0,001 – …;

Any term of the geometric progression can be calculated from the following expression:

an=a1qn - 1,

Here: a1 - the first number (term), q - the divisor of the geometric progression.

Geometric progression has several advantages:

-

The relative difference of any two adjacent terms is constant, for example 1 – 2 – 4 – 8 – 16 – 32 – 64.., where the arbitrary term is 100% greater than its predecessor.

-

Multiplication or division of arbitrary terms of a geometric progression is also a term of this progression.

A geometric progression is considered capable of interrelating not only linearly related parameters, but also quadratic and cubic and other related parameters.

The selected number series must be able to meet the following requirements:

-

It is necessary to recommend a system of rational lines that meets the requirements of production and use;

-

It should be infinite both in the direction of large numbers and in the direction of small numbers;

-

Must have values that are multiples of one and an arbitrary number;

-

It should be simple and easy to remember.

9.1 - table

number |

Swe |

number |

Swe |

number |

Swe |

number |

Swe |

number |

Son |

012345678 |

1,001,061.121,181,251,321,401,501,60 |

910111213141516 |

1.701.801,902,002.122,242,362,50 |

1718192021222324 |

2,652,803,003.153,353,553,754,00 |

2526272829303132 |

4,254,504,755,005,305,606,006,30 |

3334353637383940 |

6,707,107,508,008,509,009,5010,00 |

Special studies show that the series that best meets all the above requirements is the series of geometric progression that multiplies each n term by ten times. According to the condition

an= 10a

In that case,

aqn= 10a

from this

q =

GOST 8032 – 84 international standard recommends four main and two additional selected lines, and additional lines can be used only in special cases, technically justified cases. 8.1. – the table shows the rounded values of selected numbers in the decimal interval from 40 to 1 of one of the main lines R10.

9.3. Mahsoot haqstandardization of information in

and coding

When we buy products, we see shapes marked with different thickness lines and numbers on their package (box) or label -m barcodes. Here's some information about what the bar codes mean and when they appeared.

The idea of applying barcodes to products was first created in the 30s at Harvard Business School in the USA, and its practical use began only a few decades later, in the 60s. The first users of bar codes were railwaymen, who used this method to identify railway cars. The rapid development of microprocessor technology made it possible to widely use barcodes from the 70s. In 1973, the Universal Product Code (IPC) was adopted in the USA, and in 1977, the European Coding System - EAN (European Article Numbering) was established, and now it is widely used not only in Europe, but also in other regions. The bar code consists of alternating black (bar) and white (problem) colored lines of different thicknesses, and the sizes of these lines are standardized. Barcodes are designed to be read using special optical devices - scanners. By means of it, through microprocessors, the bars are decoded into numbers, and the information about the product is transferred to the computer.

In many economically developed countries, it is mandatory to have a barcode on the packaging of the product. Otherwise, trade organizations may refuse the product. This also applies to international trade. The economic efficiency of this system is evident when more than 85% of the product is loaded. In addition, it has a special place in forming, summarizing, taking into account the requirements and needs for the product, keeping track of the arrival and departure of the product, and carrying out the control over the storage and sale of the products.

9.2. - table

EAN code of some countries for product bar coding

State code |

State name |

State code |

State name |

State code |

State name |

93 |

Australia |

539 |

Ireland |

621 |

Suriya |

90 – 91 |

Austria |

569 |

Iceland |

00 – 13 |

USA and Canada |

779 |

Argentina |

84 |

Spain |

869 |

Turkey |

476 |

Azerbaijan |

80 – 83 |

Italy |

471 |

Tayvan |

54 |

Belgium and Luxembourg |

529 |

Cyprus |

482 |

Ukraine |

481 |

Belarussiya |

850 |

Cuba |

64 |

Finland |

380 |

Bulgaria |

477 |

Lithuania |

30 – 37 |

France |

789 |

Brazil |

750 |

Meksika |

859 |

Czech Republic |

50 |

Buyuk britaniya |

622 |

Egypt |

780 |

Chile |

599 |

Hungary |

87 |

The Netherlands |

73 |

Sweden |

759 |

Venezuela |

94 |

New Zealand |

76 |

Switzerland |

40-44 |

Germany |

70 |

Norway |

860 |

Yugoslavia |

489 |

Hong Kong |

590 |

Poland |

880 |

South Korea |

486 |

Georgia |

560 |

Portugal |

600 – 601 |

South Africa |

520 |

Greece |

460 – 469 |

Rossiya |

45 – 49 |

Japan |

57 |

daniya |

88 |

Singapore |

478 |

Uzbekistan |

729 |

Israel |

383 |

Slovenia |

487 |

Kazakhstan |